Máy đo lực xoắn kỹ thuật số không dây HIOS

Model: HP-100 (Không dây)

Phạm vi đo đỉnh: 0,15-10N・m/ 15-1000N cm

Độ chính xác: Trong vòng ±0,5% (FS)

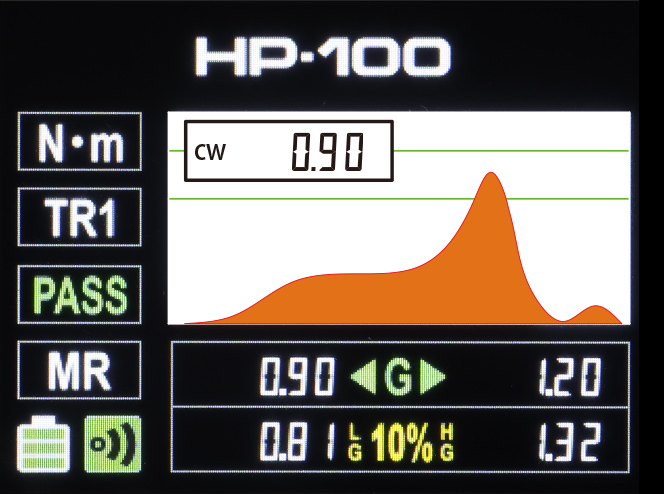

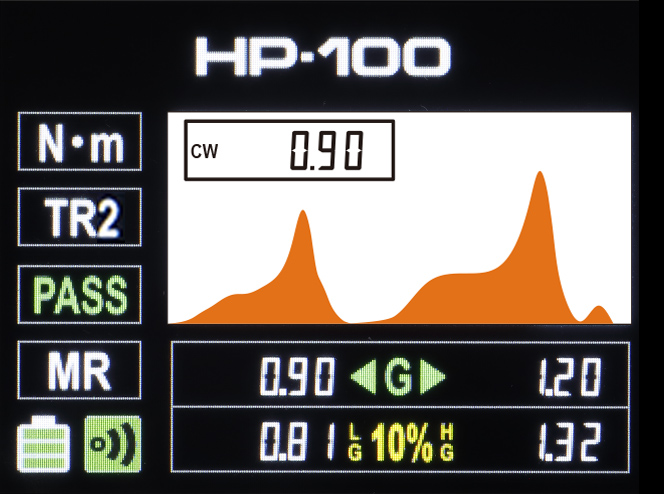

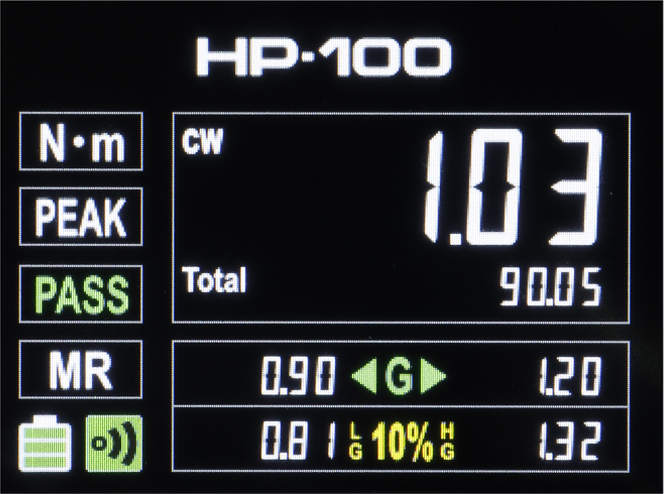

Chế độ đo: TR1 (dạng sóng), TR2 (dạng sóng liên tục), PEAK (đỉnh)

Kích thước bên ngoài230×110×50(H) (mm)

Trọng lượng 1,94kg(g)

Nguồn điện (thời gian sạc): Pin niken-kim loại hydride 1.000mA (5 giờ)

Có thể sạc lại khoảng: AC100-240V (50/60Hz)

Kiểm tra và quản lý mô-men xoắn có độ chính xác cao cho tua vít điện, tua vít lực, cờ lê lực, v.v.

Được trang bị chức năng giao tiếp không dây, dạng sóng mô-men xoắn được đo được sẽ hiển thị dưới dạng đồ họa trên màn hình lớn, cải thiện đáng kể khả năng hiển thị và khả năng vận hành.

High-precision torque check and management for electric screwdrivers, torque screwdrivers, torque wrenches, etc.

HIOS Wireless Digital Torque Meter

Model: HP-100 (Wireless)

Peak measurement range

0.15-10N・m/ 15-1000N cm

Accuracy: Within ±0.5% (FS)

Measurement Mode: TR1 (waveform), TR2 (continuous waveform), PEAK (peak)

External dimensions230×110×50(H) (mm)

Weight 1.94kg(g)

Power source (charging time): 1,000mA nickel-metal hydride battery (5 hours)

Can be recharged approximately : AC100-240V (50/60Hz)

● A wireless model has been released. Measurement data can be transferred wirelessly regardless of the measurement location. Cost reduction achieved by digitalizing and going paperless on-site.

● Wired data output is also standard. Measurement results can be used for quality control records and maintenance.

● An improved display. The larger display makes it easier to see and use.

● Measurement mode now features a waveform mode that visually displays the progression of torque values. Changes from the start of rotation to the peak and abnormal torque value detection are visualized, allowing for more detailed quality checks.

● Measurements in CW (clockwise) and CCW (counterclockwise)

● Measurement units can be switched (N.m ←→ N.cm)

● Inspection report included with all products.

● Can issue various product certificates, such as calibration certificates and traceability system diagrams.

The measured torque data can be transferred to a PC or control device. Various connection methods are available, for example, using wireless technology or connecting to a PC with a USB cable.

The main unit settings can also be controlled from an external control device. The measured data is transferred to a PC and can be easily collected and stored via an application. The data can also be exported to a CSV file for use in evaluation and analysis tools.

Maintenance and calibration :

► We also have calibration certificate attached ( optional )

► Please re-calibrate after use for a certain period through our purchase store.

DISTRIBUTED BY:

Semiki instrumentation Co., Ltd

Email: sales@semiki.com

Office tel: +84 28 2253 3522

~DOING OUR BEST FOR YOU~